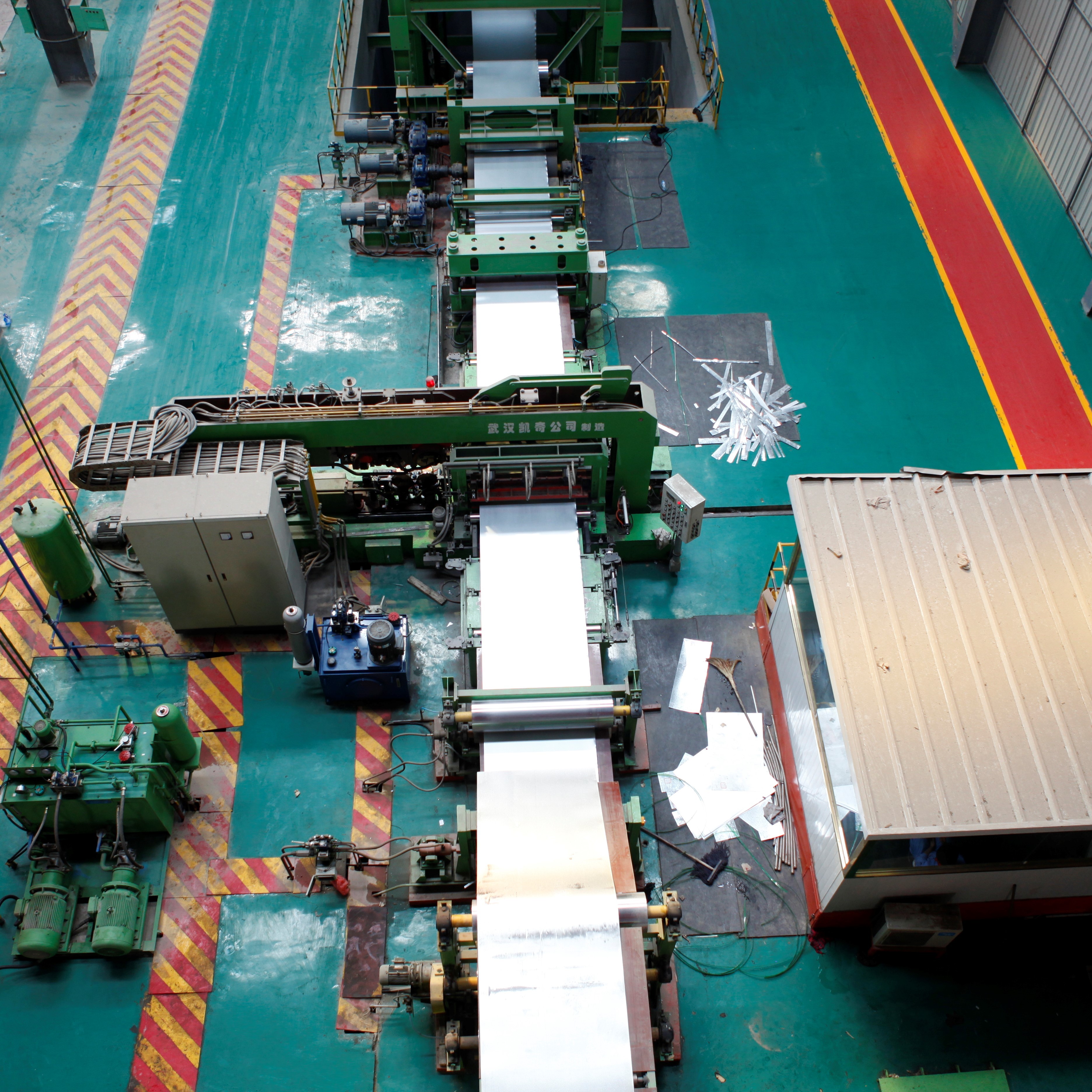

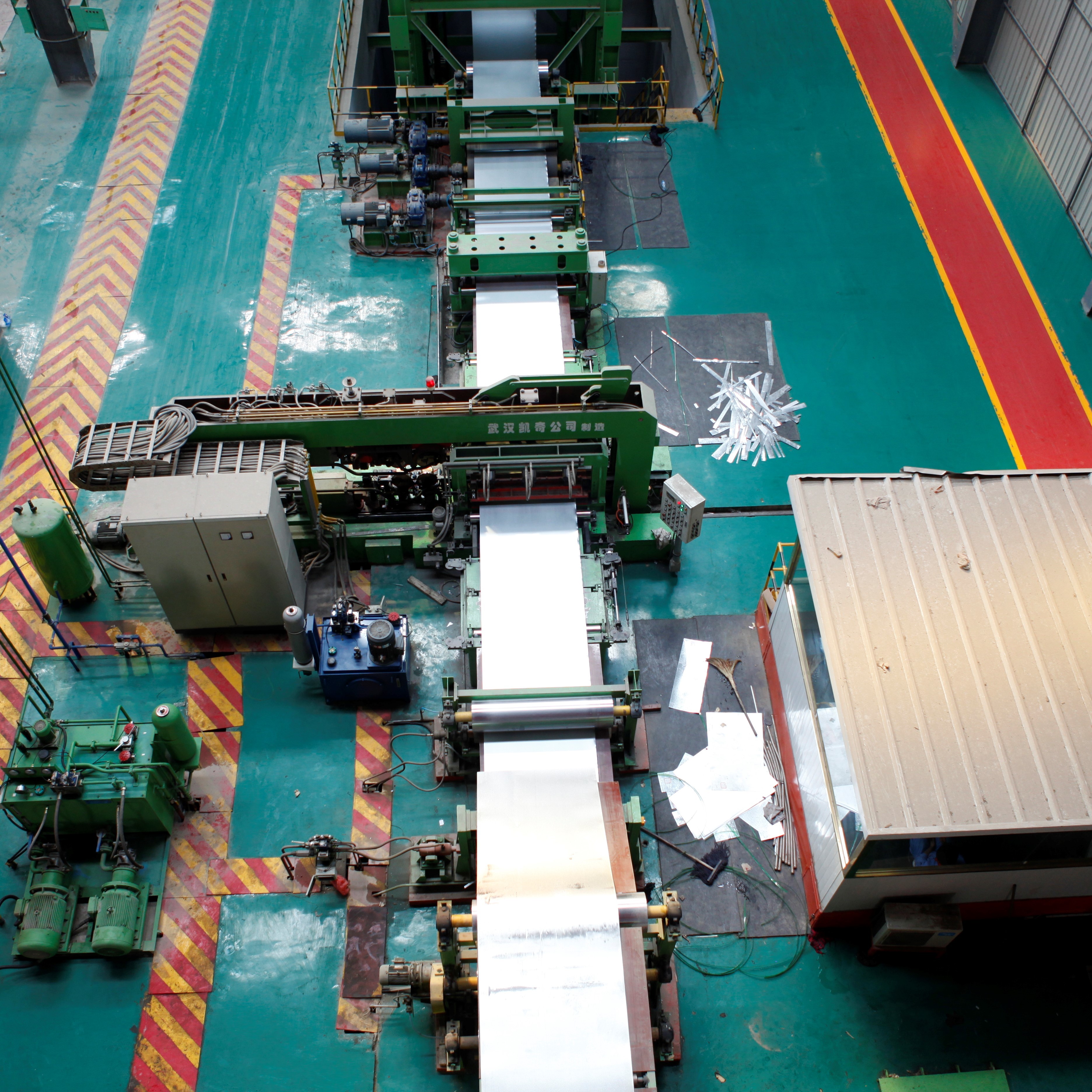

Continuous Galvalume Line for Cold Rolled Coils

The continuous hot - dip galvanizing/galvalume line is a set of

equipments that plating a layer of zinc or aluminum alloy on the

strip while in high temperature. The production line was composed

of uncoiler, welder, storage tank, degreasing section equipments,

continuous annealing furnace, zinc pot, air knife, skin pass,

tension leveler, oiler, shear, recoiler and other equipments.

JJRS assembles excellent technology research team, high qualified

management personnel, perfect management system and powerful

engineering design and complete project capability. As an

integrated solution provider, we are willing to provide iron and

steel enterprises of all over the world with highest quality

products and services, from general engineering contracting,

integrated production lines, to single equipment, even components

and spare parts.

Brief Introduction of 0.25~2.2mm*650~1350mm Continuous Galvalume

Line

The continuous galvalume line is used to produce high quality

galvalume steel sheets, it can realize the recrystallization

annealing of cold rolled steel strip and deposit an equal thickness

coating on the surface.

Technical Process

Coil loading → Decoiling →Head Cutting → Entry Looper → Degreasing

(Alkali Spray+Alkali

Brush+Electrolysis Cleaning + Water Brush + Water Cleaning)→ Hot

Air Drying → Annealing

Reduction → Galvanizing → Air Cooling → Water Quenching Cooling →

Air Jet Dry → Skin

Pass → Tension Leveling → Passivation → Exit Looper → Oiling

(reserve)→ Cutting →

Recoiling → Coil Unloading → Packing.

Packing and Shipping

1) Seaworthy package and necessary measure is taken to protect the

Equipment from moisture,

rain, rust, corrosion, shock and damages according to their

different shapes and special features.

2) With clear pack list outside and inside the case .

3) In accordance with the characteristics and different

requirements in loading, unloading and

shipping different equipment, the package is conspicuously marked

with "HANDLE WITH

CARE", "RIGHT SIDE UP","KEEP DRY", ect.

Technical Parameters| Material | Hot rolled coil, cold rlled coil |

| Width | 650mm~1350mm |

| Thickness | 0.25mm~1.6mm |

| Type | Continuous |

| capacity | 150,000t/year |